Rope Characteristics

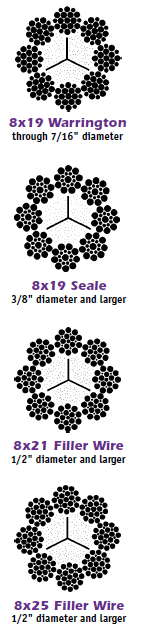

- Offer a wide range of constructions and diameters

- Manufactured predominently with a natural fiber core

- Provide an average service life of eight to ten years

- Produced using softer grades of steel than ropes used in other markets

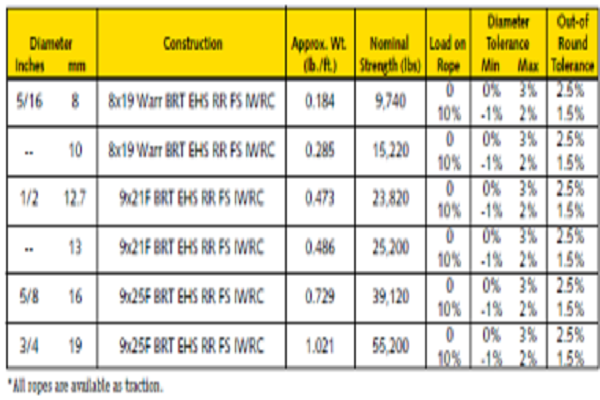

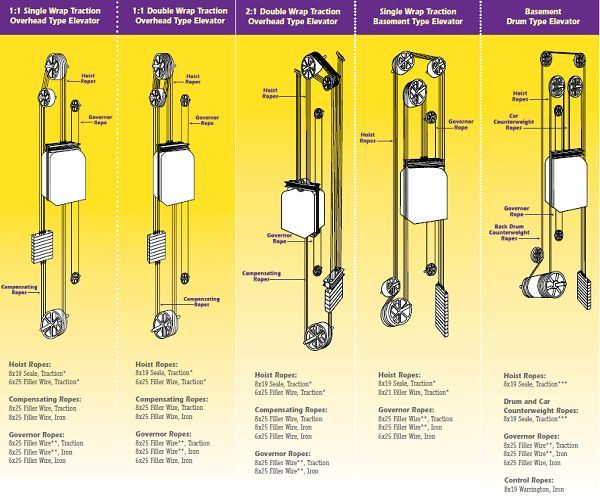

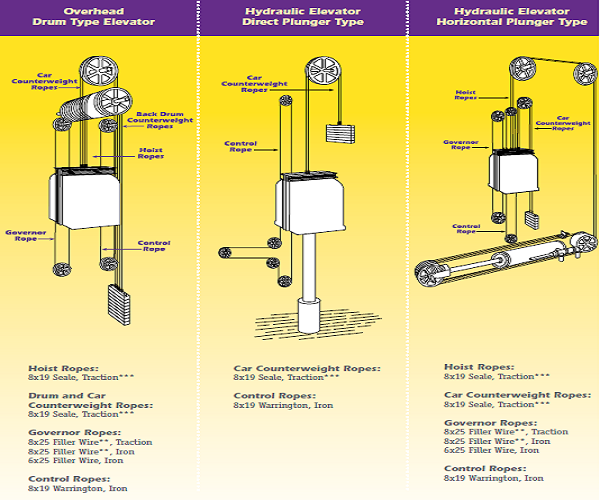

Standard Elevator Rope

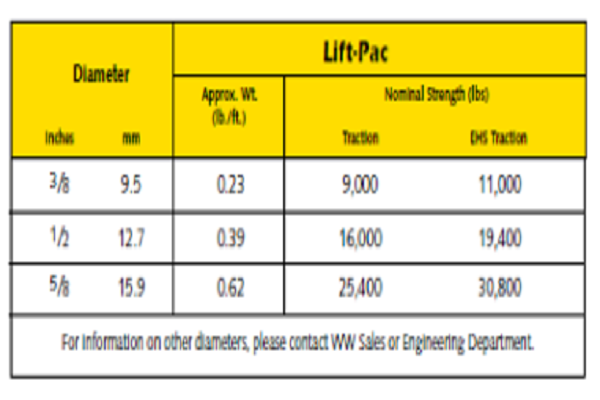

Hoist Ropes

With the advent of high rise elevators and increased car speeds, elevator designers and manufacturers frequently select a higher strength hoist rope. The grade of steel (traction, extra high strength traction) is dependent upon many factors, the most critical being load requirement and car speed. It is not always advantageous to use an EHS traction rope where traction will suffice. The low carbon wire used on traction grade wire ropes may provide better fatigue life than a higher carbon EHS wire.

.png)

.png)